There are a few characteristics of foam mattresses that many tend to confuse with one another. As you shop for the best mattress for your needs, it’s important that you’re able to distinguish these differences. Otherwise, you may make a seemingly minor mistake in thinking that can significantly impact the overall comfort and satisfaction you experience with the product you decide to purchase. Today, I’m going to walk you through everything you need to understand about foam densities as you’re sure to come across these types of specs as you shop around.

A Quick Clarification

One of the most common misunderstandings when it comes to density levels is an association with firmness. What many will mistakenly take away from density specs is that higher numbers mean a firmer mattress. If you are guilty of this, you’re certainly not alone, and it’s certainly understandable where the misunderstanding comes from. What density really reveals to you is quality and durability expectations.

You can typically expect mattresses featuring higher densities to be heavier and more solid. Lower densities, on the other hand, are lighter and easier to move around. However, with higher densities, you can often expect the increase in the compression of material to provide better durability.

Now, firmness is another important factor, and, what you need to look for in your examination of this aspect is indentation load deflection, NOT density. We offer a comprehensive guide that can help you better understand ILD which is well worth checking out.

What are Foam Density Ratings?

The density of a material is defined as its mass per unit volume. In layman’s terms, this describes how tightly the matter is compacted. Discovered by Greek scientist Archimedes, it’s calculated by dividing mass by volume.

Many would tend to think that a higher density would mean the material is more compact and therefore more firm. However, this isn’t the case when dealing with foam mattresses. In the industry, foam density is measured by using a square of material measuring 12” by 12” by 12”. Let’s say a product you’re considering has a density of 4 lbs./ft³. This means that the block used for measuring weighed four pounds.

As you compare densities and weights, it’s important to understand this testing process. If you come across a product with a three lbs./ft³ density, for example, this doesn’t mean the mattress itself weighs three pounds as it’s actual weight will be much higher. While the two terms are directly related and an increase in overall weight will mean a higher density and often increased durability, density refers to the small sample size. Therefore, correlating the terms “density” and “weight” can cause some confusion as you examine specs.

Important Aspect for Those Who Carry More Weight

If you carry a lot of weight, density is a very important factor that you’ll want to carefully consider, and this is because it will impact your level of comfort and the durability of the product you choose. Pay careful attention to the top five or six inches of the mattress as this is the area that tends to break down more quickly and develops problems such as sinkage and softening.

Heavier people obviously sink into the material more deeply, and you want to find a product with a high expectation of durability. Therefore, a higher density would be more compatible with your unique needs.

Analyzing Densities of Various Foam Types

There are many different types of foam on the market, and you’ve likely come across quite a few of these as you’ve shopped around. Since these materials are produced using different processes, there are aspects related to density that you should be on the lookout for, and it’s worth examining them a little more closely to help guide you.

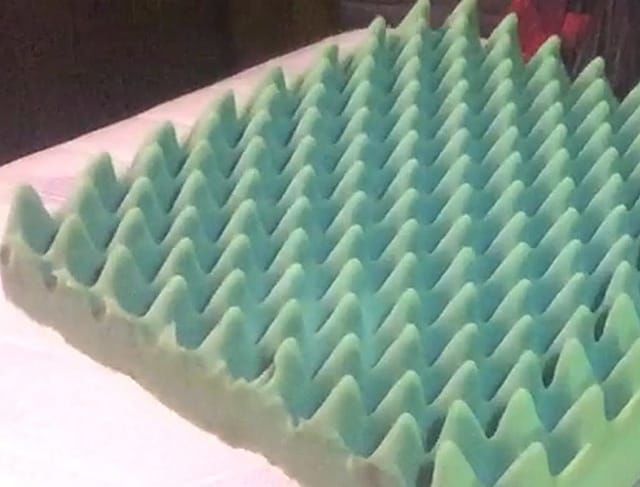

— Polyfoam

As you analyze the comfort layers on polyfoam, a good guideline is to look for one comprised of a medium density foam of at least 1.8 lbs./ft³ for one-sided products and at least 1.5 lbs./ft³ for double-sided mattresses. However, if you carry more weight, you’re going to want to keep your bare minimum at two lbs./ft³.

As with most things in life, you get what you pay for, and money can be tight. If you are working on a limited budget, polyfoam is often a good choice as it is typically the least expensive, but you may have to compromise here. If you go for a product with a density of less than 1.5 lbs./ft³, just make sure that the tradeoff on the cheaper price is worth the long-term decline in comfort you’ll be making. If the mattress is to be used sparingly, in say an RV or guest bed, then you don’t need to worry as much about density levels in a foam mattress.

Hybrid Products

Some products on the market will use various forms of foam in the same mattress, and a trend is to use polyfoam as the base. This is because it is easy to compress and reduces costs in shipping. However, keep in mind that the base acts as your foundation. Since the densities of polyfoam are often low, these products often tend to deteriorate more quickly.

Importance of Higher Densities in the Top Layers

Your weight impacts the top layers directly, and that’s why it’s important to consider just how long you want your product to last. Lower-density foams on the top layer can easily begin to degrade within the first year of use. While saving money is important, will you be ready to replace the mattress this quickly? The high density foam mattress advantages are typically worth added initial investment.

High Density Polyfoam

While high density polyfoam would typically be defined as one that measures 1.5 lbs./ft³, I feel 1.8 lbs./ft³ is a better guideline. This is because:

- It lasts longer

- It features a higher level of performance and compression

- It is better suited for use in the comfort layers of the product

If you do come across a product with a 1.5 lbs./ft³ mattress foam density, I would advise that you ensure this layer is thin or the product is two-sided. As you shop, never hesitate to contact customer service to ask about these qualities. Often, you will find that they are hesitant to delve too much into density levels, there’s a good chance their manufacturing process takes shortcuts that decrease the durability you can expect to achieve.

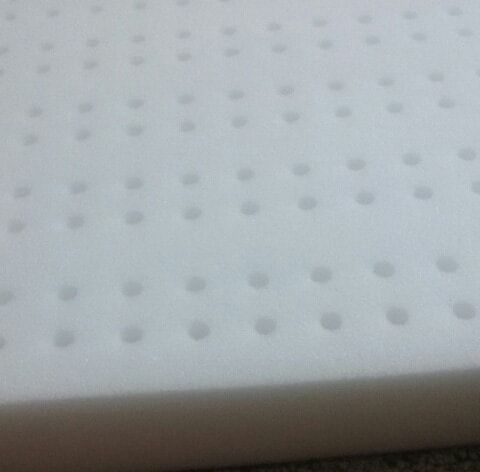

— Memory Foam

Also known as viscoelastic foam, memory foam was designed in the 1960’s to be used for NASA airplane seats. It responds to body heat and pressure to evenly distribute weight, and it’s well-known for its ability to limit motion transfer as its original design was intended to absorb energy to protect pilots. This technology was later implemented into the mattress industry, and there are now many varieties of quality memory foam products to choose from.

Unlike polyfoam, memory foam is typically denser and more costly. However, some people don’t like that it sinks in as your body heats it up as this can make it difficult to turn over throughout the night. Some, on the other hand, enjoy this feature, so it’s all about personal preference. There is something that memory foam and polyfoam have in common, however, and this is the fact that lower densities translate to lower durability, so let’s explore the ranges to be on the lookout for.

Medium Density Memory Foam

A quality memory foam mattress you can expect to last should have at least a 3.5 to 4 lbs./ft³ density as anything less than this is low density foam and not as durable. Furthermore, if you are heavy, I would not settle for anything less than five lbs./ft³ if you want your product to last. It’s my goal that you make the best choice for you. If your budget simply won’t allow for the purchase of a memory foam product with a density in this range, it would be my strong suggestion to consider another material that can offer you the quality you deserve.

However, if you’re attracted to the features of memory foam, just make sure that you’re prepared to compromise on durability and that the price is worth this tradeoff. If the memory foam layer is more than an inch thick and with a density under 3.5 lbs./ft³, I would steer clear. You could also consider the purchase of a quality memory foam topper. This allows you to enjoy the features of memory foam at a fraction of the cost

High Density Memory Foam

If you find a product with a density of six lbs./ft³ or more, you can expect a hike in the cost. However, these are some of the best density for memory foam mattress. You can be confident that the product will offer superior support and last a long time. This can be a great choice if you have the money and are looking to make a long-term investment. I would suggest you actually sleep on a memory foam mattress before making such a purchase as you want to be sure you’re committed to this type of foam. You may notice it feels hard at first, but, as you lay on it, it will mold to your body and:

- Offer pressure support

- Improve circulation

- Relieve aches and pains

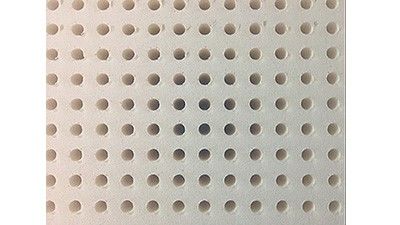

— Latex Foam

Latex is often the material-of-choice due to the fact that, in general, it’s highly durable. Therefore, if you’re shopping for a latex product, you should focus more on the blend when considering the longevity expectation of the product.

Natural vs. Synthetic

Latex foams are made from one of two raw materials: natural and synthetic. Natural latex is extruded from the rubber tree, and it’s typically more elastic. You can also expect to pay a higher price for this latex type. If you’re on a budget, you may prefer to go with a synthetic latex, but these products typically have a lower resistance to degradation over time. Furthermore, there are hybrid products on the market which use combinations of both natural and synthetic latex.

Natural Latex

Synthetic Latex

Talalay vs. Dunlop

Using these two materials, there are two foaming processes that are used to create mattress foam. Dunlop was the original process in latex foam creation, and it results in a denser end-product. Talalay was later innovated, and it takes the Dunlop process a little bit further in that a vacuum is used to remove air from the foam before the mold is frozen, and this can help create better air flow. For a full overview complete with a video of the Talalay process, we have everything you need to know.

No matter what material, foaming process or blend you decide to go with, you can remain confident that the material should be highly durable. As you shop, however, there are some general guidelines in an ascending price order to keep in mind:

Dunlop

Talalay

Dunlop

- Least expensive

- High density, so it’s better suited as a base as opposed to a comfort layer

- Simple manufacturing process

Blended Talalay

- Offers the features of both natural and synthetic latex

Synthetic Talalay

- Varying firmness levels, unlike Dunlop, so it can be suitable as a comfort layer

- Great for use in swappable mattresses with zippers

- Not as ideal for a base as Dunlop due to density

Natural Talalay

- Typically most expensive latex option

- Health and environmental benefits

Bringing It All Together

Overall, density is a very important factor to take into consideration as you shop for your mattress. If you are heavy, you should carefully analyze this aspect as it will make a big difference in your experience, and you can use our helpful density guide chart to make the best choice on a durability standpoint.

We understand it can be confusing with all the various foams on the market, and I hope you have found this guide to be helpful in breaking down the differences.

Foam Density Chart

| Material | Low Density | Med. Density | High Density |

|---|---|---|---|

| Polyfoam | < 1.5 lbs | 1.5-1.8 lbs | > 1.8 |

| Memory Foam | > 4 lbs | 4-5 lbs | < 5 lbs |

Foam Quality and Durability Chart

| Material | Quality | Durability | Cost |

|---|---|---|---|

| Polyfoam Low Density | Poor | Poor | Low |

| Polyfoam Medium Density | Poor | Poor | Low |

| Polyfoam High Density | Medium | Medium | Low |

| Memory Foam Low Density | Medium | Medium | Medium |

| Memory Foam Medium Density | High | High | High |

| Memory Foam High Density | Very high | Very high | High |

| Dunlop Latex | Medium | High | Low |

| Synthetic Talalay Latex | High | High | Medium |

| Blended Talalay Latex | High | High | Medium |

| Natural Latex | High | High | High |